Work rolls for cold steel and non-ferrous alloys rolling mills

Category

Rolling-mill equipment and rollsAbout This Project

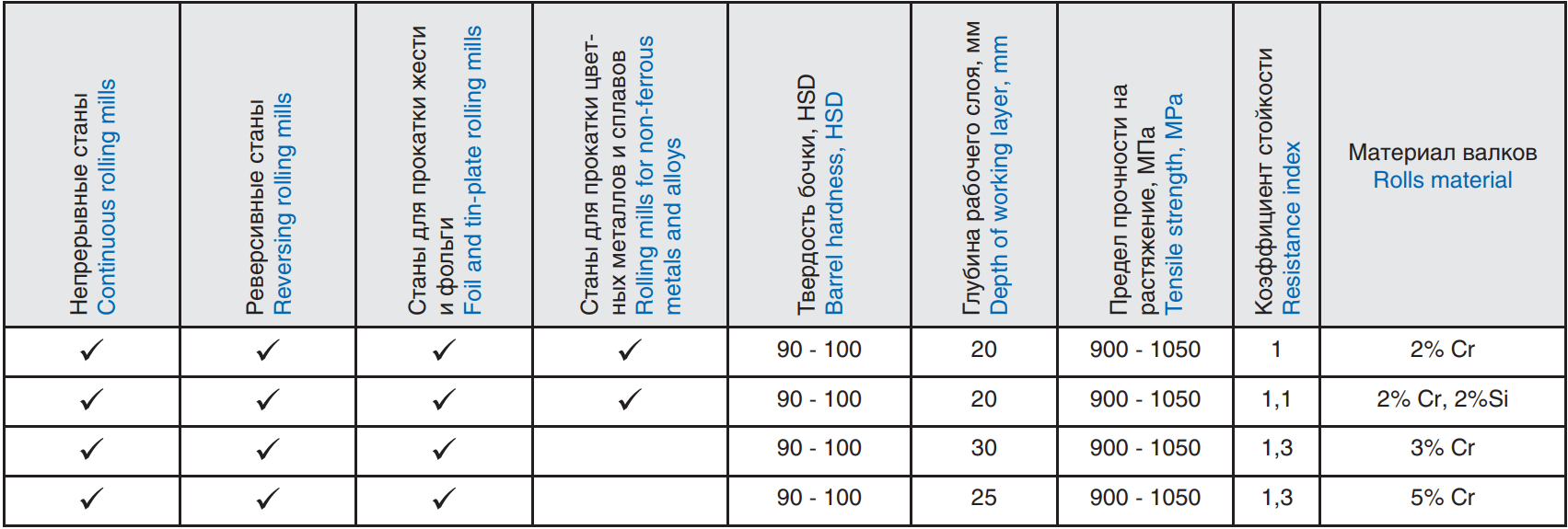

- High wear resistance and resistance to thermal «shocks» at emergencies in the mill.

- Forged homogeneous structure excluding the presence of weaknesses and pores.

- High level of barrel and necks strength properties.

- Sufficient resistance to development of contact and fatigue cracks.

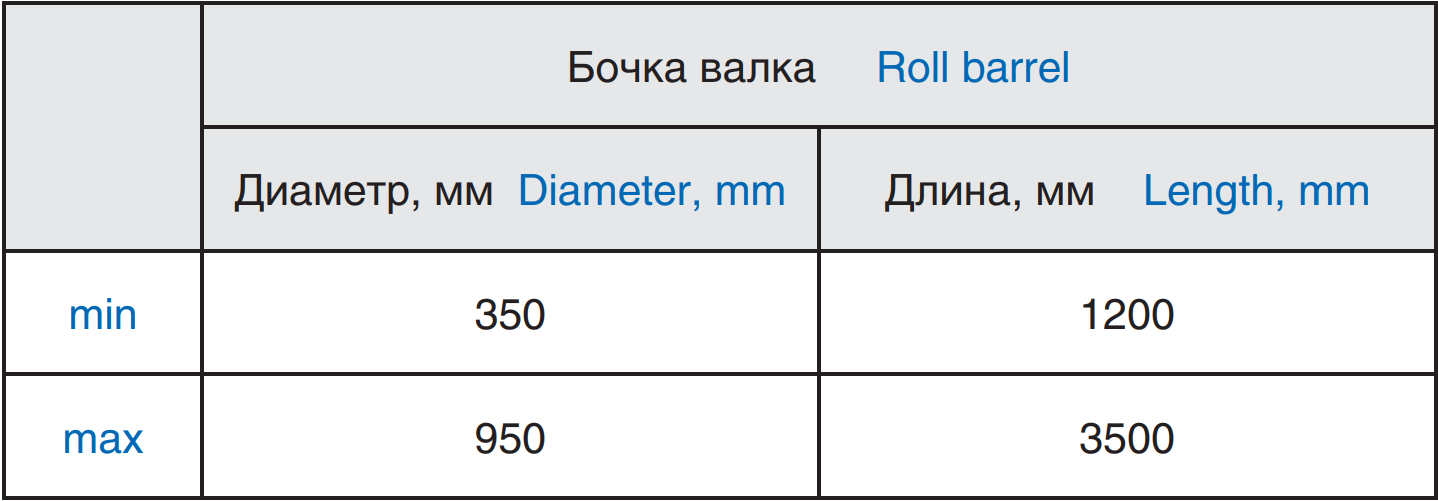

- Depth of hardening layer up to 30 mm per radius.

- Uniform wear profile.

- High performance characteristics ensured by balanced campaign period and regrinding scope.

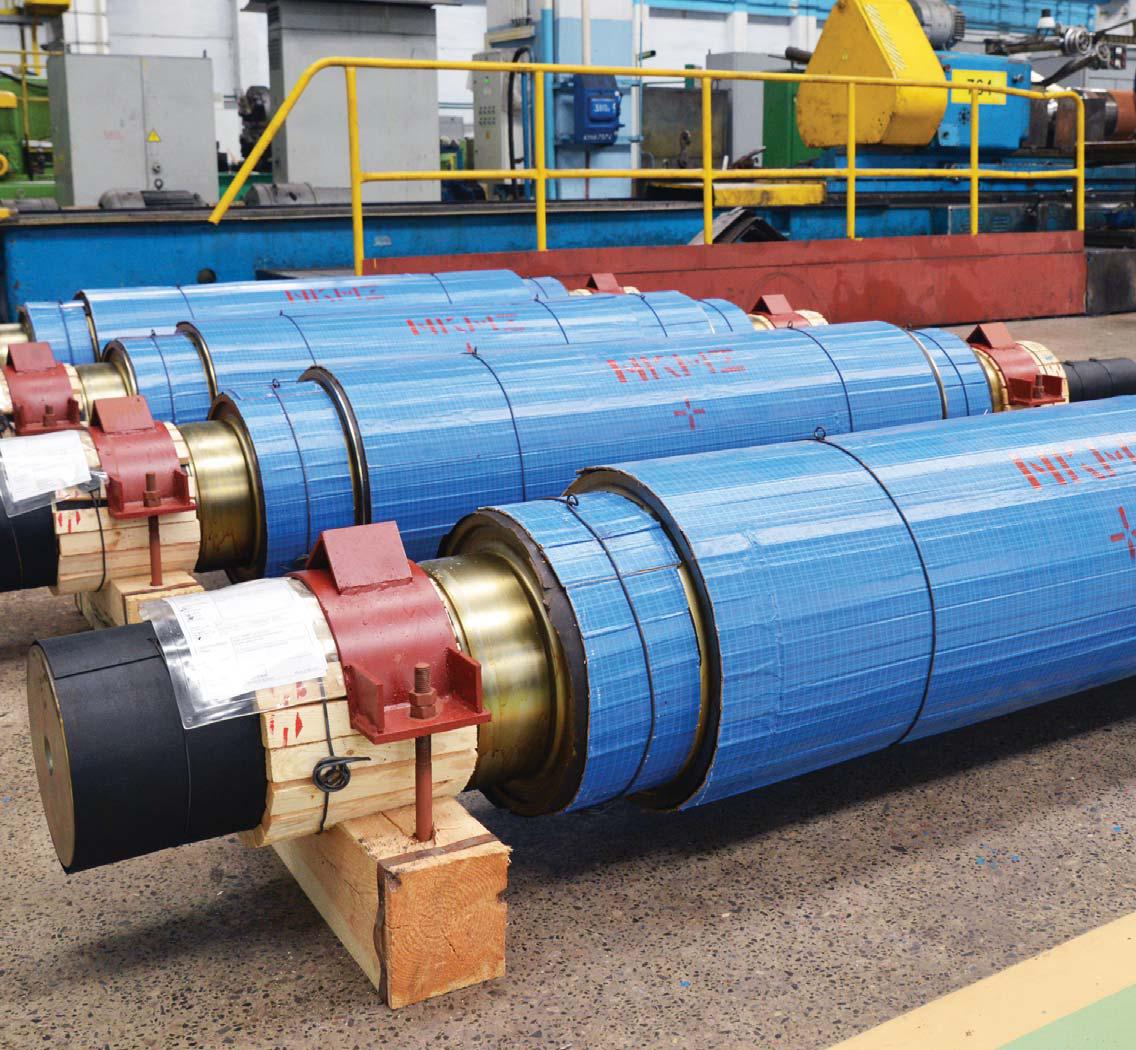

Roll production technical capabilities – 180-200 rolls/month.

Rolls are produced from especially high-quality alloyed steel grades. They are distinguished by high hardness for the depth up to 30 mm which provides the increased resistance in severe conditions of high-speed rolling, followed by heat shocks during operation.

Barrel hardness variation – max 3 HSD